Why Your Furnace Blower Motor is Critical for Henderson Home Comfort

Furnace blower motor repair henderson becomes essential when your home’s heating system starts struggling to circulate warm air effectively. The blower motor is the heart of your furnace’s air circulation system – without it working properly, even a perfectly functioning heating element can’t deliver comfort to your rooms.

Quick Answer for Henderson Homeowners:

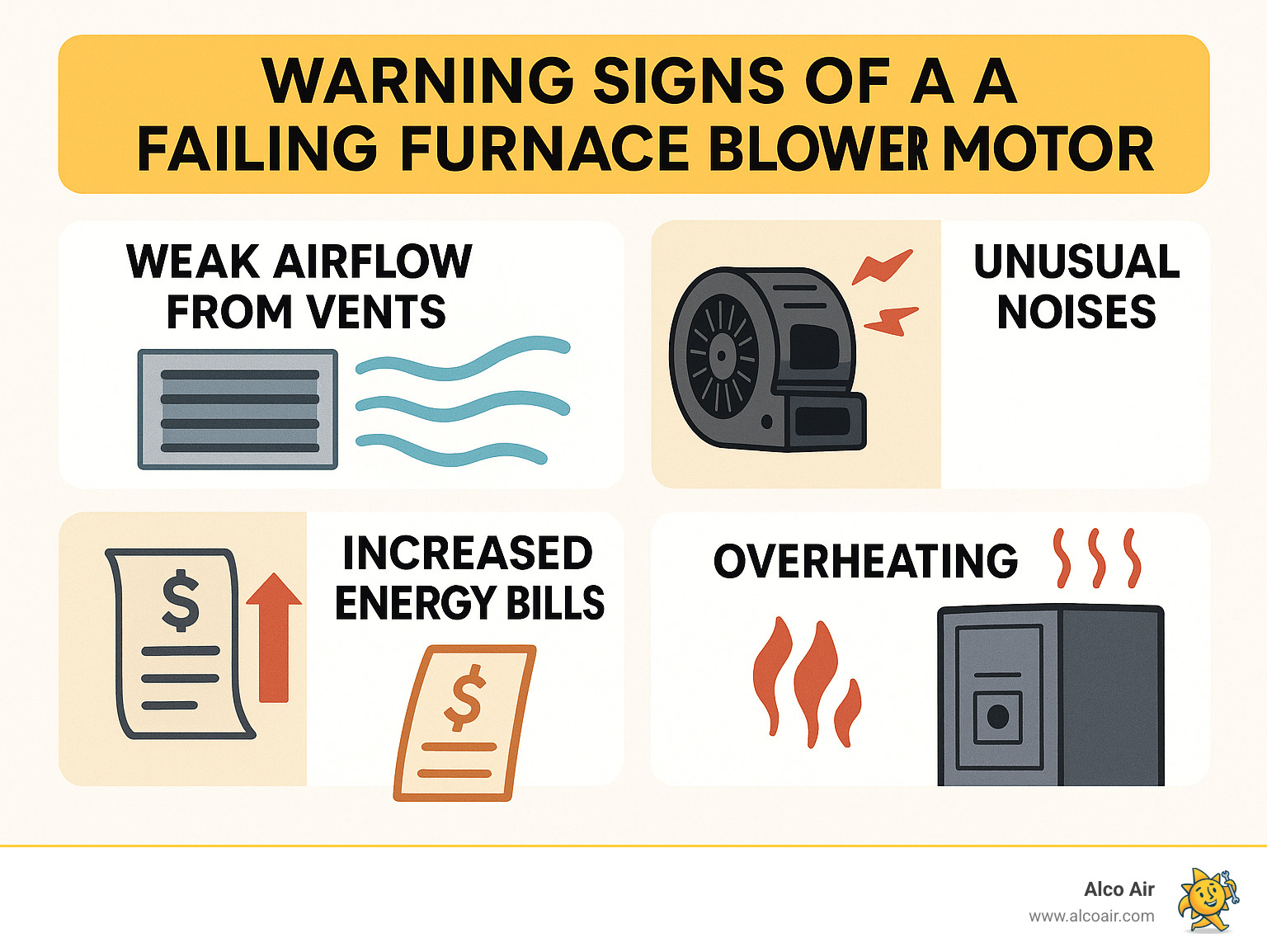

- Common signs: Weak airflow, strange noises, high energy bills

- Typical causes: Dirty filters, electrical issues, normal wear and tear

- Professional process: Diagnosis → Testing → Repair/Replace → System verification

- Cost factors: Motor age, extent of damage, furnace condition

- Prevention: Regular filter changes and annual maintenance

In Henderson’s variable climate, your furnace works hard during those unexpectedly cold Texas winters. When temperatures drop, a failing blower motor can leave you with uneven heating, cold spots, and skyrocketing energy bills.

Many homeowners don’t realize their blower motor is struggling until it completely fails. But there are clear warning signs that can help you catch problems early and avoid emergency repairs during the coldest nights of the year.

Understanding the repair process helps you make informed decisions about whether to repair or replace your motor, and more importantly, when to call for professional help before a small issue becomes a major breakdown.

Telltale Signs Your Blower Motor Needs Attention

When your furnace blower motor starts to falter, it’s not shy about sending out distress signals. These aren’t just minor annoyances; they’re critical indicators that something is amiss and needs your attention. Ignoring them can lead to a complete system breakdown, leaving your Henderson home in the cold and facing a more complicated furnace blower motor repair henderson. We always recommend keeping an ear and an eye out for these common symptoms. If you’ve noticed any of these, it might be time to call in the pros. For a broader understanding of what might be ailing your heating system, you can also check our guide on Signs Your Heater Needs Repair.

One serious sign to watch for is if your furnace itself feels unusually hot to the touch or if it’s constantly shutting down. This could indicate an overheating furnace, often caused by a struggling blower motor that isn’t moving air effectively. When the motor can’t push enough air, heat builds up inside the furnace, which can damage components and even pose a safety risk.

Weak or No Airflow

Perhaps the most immediate and frustrating sign of a failing blower motor is a noticeable decrease in airflow from your vents, or even no air from vents at all. Instead of a steady stream of warm air, you might feel a faint whisper or nothing. This can lead to some rooms being perfectly cozy while others feel like an icebox. This is a clear sign of inconsistent temperatures and seriously reduced comfort throughout your home.

A common culprit behind weak airflow is often a clogged filter effect. Imagine trying to breathe through a pillow – that’s how your furnace feels with a dirty air filter! Dirty filters restrict airflow significantly, forcing your furnace to work harder to circulate air and causing the blower motor to strain. This extra effort can lead to premature wear and tear on the motor, making it less efficient and eventually causing it to fail. If the blower wheel issues involve it being damaged or caked with debris, it simply won’t be able to move air effectively, further reducing your comfort.

Unusual Noises During Operation

Your furnace is meant to be a quiet worker, mostly humming gently in the background. So, when it starts making strange noises, it’s usually a clear sign that the blower motor is in distress. While some clicking sounds are normal during startup or shutdown, persistent or new noises demand your attention.

- Screeching or Squealing: This is typically a classic sign of worn-out bearings in the blower motor. Think of it like a rusty gate begging for lubrication. These bearings allow the motor to spin smoothly, and when they dry out or wear down, they create a high-pitched protest. Ignoring this can lead to the motor seizing up entirely.

- Grinding Sounds: A deep, unsettling grinding noise can indicate that the motor’s bearings have completely failed, or that there’s an issue with the motor’s internal components rubbing against each other. This is a serious sound that suggests imminent failure and a call for immediate furnace blower motor repair henderson.

- Banging Loose Parts: These sounds might suggest loose parts within the blower assembly or a blower wheel that has become unbalanced or loose on its shaft. It’s like your furnace has started its own little percussion section, and it’s not a good sign. A loose blower wheel can cause vibrations and eventually damage the motor or its housing.

- Humming or Buzzing: If you hear a humming or buzzing sound but no air is coming out of your vents, it could indicate an electrical issue. The motor might be receiving power but is unable to start spinning, perhaps due to a faulty capacitor or a seized motor. It’s getting power, but it just can’t get going.

Any of these sounds are your furnace’s way of telling you it needs help. Addressing them promptly can prevent more extensive and costly repairs down the road.

Skyrocketing Energy Bills

Have you noticed your energy bills climbing without a clear explanation, even though you haven’t changed your thermostat settings? A failing furnace blower motor could be the sneaky culprit behind those high energy bills. When the motor inefficiency sets in, your entire heating system has to work harder and longer to try and reach your desired temperature.

This constant struggle means your furnace consumes more energy to do the same job, directly translating to higher utility costs and an increased cost of operation. A healthy blower motor ensures optimal airflow, allowing your furnace to heat your home effectively and efficiently. When it’s struggling, it loses efficiency, forcing the unit to run for extended periods. This means your system working harder for less output, leading to reduced performance and that unwelcome spike in your energy statement. It’s a clear sign that your system is under duress, and a professional diagnosis can help identify if a failing blower motor is indeed the cause.

Common Causes of Furnace Blower Motor Failure

Nobody wants to think about their furnace breaking down, but understanding what causes blower motor failure can save you from unexpected cold nights and costly repairs. The good news? Many of these issues are completely preventable with a little attention and care. When Henderson homeowners need furnace blower motor repair henderson, it’s usually because one of these common culprits has been quietly working behind the scenes.

Neglected Maintenance and Dirty Filters

Here’s the truth that might sting a little: most blower motor problems could have been avoided with regular maintenance. Your air filter might look innocent enough, but when it gets clogged with dust, pet hair, and debris, it becomes your motor’s worst enemy.

Think of it this way – imagine trying to drink a thick milkshake through a tiny straw. That’s exactly what your blower motor experiences when trying to pull air through a dirty filter. The poor motor has to work overtime, straining and overheating as it struggles to move air through your home.

This constant battle doesn’t just wear out your motor faster – it also drives up your energy bills and reduces your comfort. The solution is surprisingly simple: change your air filters every 1 to 3 months. If you have pets or family members with allergies, you might need to change them even more frequently.

We see this so often that we can’t emphasize it enough. Regular filter changes are like giving your furnace a breath of fresh air. For more comprehensive care tips, check out our Furnace Maintenance guide.

Electrical Problems and Component Wear

Sometimes, even well-maintained furnaces develop problems due to electrical issues or normal wear and tear. These problems often require a trained eye to diagnose properly, but understanding them helps you know when to call for help.

Failing capacitors are among the most common electrical culprits. This small, cylindrical component acts like a battery that gives your motor the electrical boost it needs to start spinning. When it weakens or fails, your motor might hum loudly but refuse to start, or it might struggle to reach full speed. The good news is that capacitor replacement is usually straightforward and affordable.

Worn bearings are another frequent issue, especially in older systems. These tiny components allow your motor’s shaft to spin smoothly, but over time they can dry out or accumulate dirt. When bearings start to fail, you’ll hear those telltale screeching or grinding sounds we discussed earlier. Sometimes lubrication can help, but often the bearings need replacement.

Frayed wiring and loose connections create intermittent problems that can be frustrating to diagnose. Corroded connections can cause your motor to work inconsistently, while damaged wiring poses serious safety risks including potential fires.

Finally, there’s simple age-related decline. Just like your car, your furnace components wear out over time. Most furnace systems last 15-20 years, and the blower motor works harder than almost any other component. If your system is approaching this age range, motor problems might simply be a sign that it’s time to start planning for replacement. You can learn more about how heating systems work by checking out this resource on central heating systems.

The key is catching these issues early, before a minor problem turns into a major headache on the coldest night of the year.

The Professional Process for Furnace Blower Motor Repair in Henderson

When your furnace acts up, it can feel like a mystery. But for our skilled technicians, it’s a puzzle they’re expertly trained to solve! When you call us for furnace blower motor repair henderson, you’re not just getting a quick fix. You’re getting a thorough, systematic approach designed to ensure your heating system is safe, efficient, and ready to keep you cozy for the long haul. Our NATE-certified technicians follow a precise process to diagnose, repair, and test your blower motor, making sure everything is just right.

Step 1: Diagnosis and Inspection

Before we even touch your furnace, safety is our absolute top priority. We always start by disconnecting power to the furnace, usually by flipping the circuit breaker in your home’s electrical panel. This keeps everyone safe from electrical hazards.

Once the power is off, our technician begins a comprehensive inspection. Think of it like a detective gathering clues! We perform a visual check, looking for any obvious signs of damage, like burnt wires, physical blockages, or excessive dirt buildup on the blower wheel and motor itself. We also verify your thermostat settings to make sure it’s actually asking for heat – sometimes, the simplest solutions are the best!

Next, we get a little more technical. We test the motor’s capacitor using a special tool called a multimeter. A weak or faulty capacitor is a super common reason a motor might act up, and thankfully, it’s often a pretty straightforward fix. We also perform a motor winding check to see if the motor itself has an internal electrical issue that would mean it needs replacing rather than just a simple repair. And finally, we inspect the fan limit switch, which is like your furnace’s internal traffic cop, telling the blower motor when to turn on and off based on temperature. If this little switch is faulty, your blower won’t know what to do!

This detailed diagnostic step ensures we pinpoint the exact cause of your furnace’s woes, whether it’s a minor electrical hiccup or a full-blown motor meltdown. For even more insights into how we troubleshoot, explore our general HVAC Troubleshooting guide.

Step 2: The Steps for Furnace Blower Motor Repair in Henderson

Once we’ve figured out what’s going on, our technician gets to work on the necessary repairs or replacement. If your motor needs replacing, here’s a peek at what typically happens:

First, we need to access the blower assembly. This is where the motor lives, tucked away in the lower section of your furnace. We carefully remove the access panels and slide out the entire assembly. Then, it’s time for removing the old motor. We gently disconnect its wiring and unmount it from the blower housing, often involving a few screws and detaching it from the blower wheel.

Before we pop in the new motor, we take a crucial step: cleaning the housing and blower wheel. You wouldn’t believe how much dust and debris can collect on those fan blades! A clean wheel ensures balanced airflow and prevents unnecessary strain on your shiny new motor. We make sure everything is spotless! Finally, we get to installing the new motor. It’s securely mounted into the housing and connected to the now-clean blower wheel. We double-check that the wheel is perfectly aligned and spins freely without any wobbling – it’s vital for good airflow and a long-lasting motor. And of course, the new motor is carefully wired according to manufacturer specifications, connecting all the right wires to the circuit board. Precision here is key for safe and efficient operation.

Step 3: Final Testing and Calibration

The repair isn’t truly complete until we’ve thoroughly tested the system. We want to be absolutely sure everything is operating perfectly before we pack up!

We start by restoring power and performing an initial startup. We listen carefully for any unusual noises and visually confirm that the blower motor is spinning smoothly. Then, we use a special tool, an amp probe, to check the amperage draw of the new motor. This tells us how much electrical current it’s using, and we compare that to what it should be using. If it’s drawing too many amps, it could signal an underlying issue that needs more attention. We also verify the rotation of the blower wheel. If it’s spinning the wrong way, you won’t get much air, so a quick visual check confirms it’s moving correctly.

Finally, and perhaps most importantly, we conduct a thorough airflow and temperature check. We feel the air coming from your vents and monitor how the temperature changes across the furnace. This ensures that the newly repaired or replaced blower motor is effectively circulating conditioned air throughout your Henderson home, bringing back that wonderful comfort and efficiency you deserve. Our meticulous process ensures your furnace blower motor repair henderson is done right the first time, giving you peace of mind and a warm, comfortable home to enjoy.

Repair vs. Replace: Making the Smart Choice for Your Home

When your furnace blower motor starts acting up, it can feel like a big moment of truth for your home’s heating system. You’re suddenly faced with a crucial decision: should you simply repair the motor, opt for a full motor replacement, or is it time to consider replacing your entire furnace? This choice isn’t always easy, and it often comes down to several important factors, like how old your furnace is, the seriousness of the problem, and what makes the most sense for your Henderson home in the long run.

Understanding the options helps you make the best decision for your comfort and your wallet. Let’s look at how these choices stack up.

| Option | Cost | Pros | Cons |

|---|---|---|---|

| Repair Motor (Minor) | Least Expensive | Quickest fix; Restores function for specific issue (e.g., capacitor); Less disruption. | Only addresses one problem; Other parts of an older motor might fail soon. |

| Replace Motor | More Expensive | New motor means better efficiency; Can extend furnace life if unit is otherwise good; Quieter operation. | Significant investment; Still relying on an older furnace; Future repairs on other components are possible. |

| Replace Entire Furnace | Most Expensive | Best energy efficiency; Full system warranty; Improved comfort features; Long-term savings on bills. | Highest upfront cost; Major installation project. |

For more detailed information on whether to repair or replace, you can visit our guide: Should You Repair or Replace Your Furnace?.

When to Repair the Blower Motor

Sometimes, a quick fix is all you need! If your furnace is relatively new and the issue is minor, like a faulty capacitor, repairing the blower motor is often the most sensible and budget-friendly choice. The capacitor is a small, inexpensive part that gives the motor the boost it needs to start. If it’s just worn out, replacing it can get your system running smoothly again without a huge expense. This is especially true if your furnace is still fairly young and has been well-maintained. It addresses the immediate problem, restoring your home’s comfort without breaking the bank.

When to Replace the Blower Motor or Entire Furnace

However, not every situation calls for a simple repair. If your furnace blower motor has suffered a major motor failure – perhaps it’s seized up or burnt out completely – and your furnace is nearing the end of its typical lifespan (often over 15 years old), then replacing just the motor might not be the best investment. An older furnace with a new motor could soon face other expensive issues, leading to a cycle of repairs.

If you’re experiencing frequent breakdowns or if the cost of the furnace blower motor repair henderson (especially for advanced, energy-efficient motors) starts to climb close to a significant portion of a new furnace’s price, then replacing the entire unit makes more sense. A new furnace brings energy efficiency gains, which can lead to significant savings on your utility bills over time, along with improved comfort and reliability. Our team at Alco Air can help you analyze the repair cost versus the long-term value of a replacement to make the smartest choice for your home.